Cylindrical Cell Battery Assembly Equipment Line for 18650/21700/26650 Preparation

Jingtong Battery Equipments offers the most professional cylindrical cell assembly equipment for 18650/21700/26650 battery laboratory research and assembly.

Item No.: JT-BDC-2

Compliance: CE Certified

Order (MOQ): 1 Set

Payment Terms: T/T, L/C, Western Union, Paypal

Product Origin: China

Warranty: One Year warranty with lifetime support

Lead Time: 7 Days

The semi-automatic pouch cell die cutting machine is mainly used for pouch cell electrode sheet cut for stacking pouch cell battery. It is a necessary tool in the production line of pouch cells to produce specific shapes of cathodes and anodes with current collector tabs.

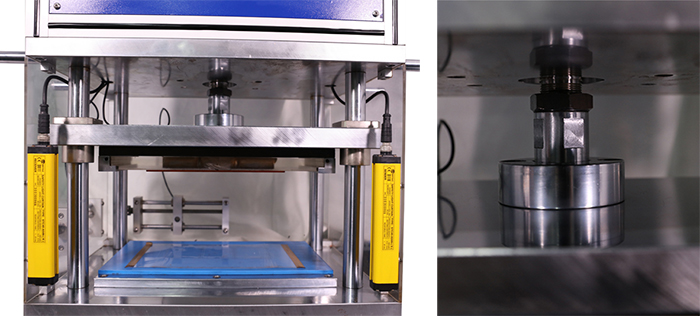

This electrode die cutting machine adopts a safety curtain built in the front of the machine and a double start button ensures operation safety when electrode sheets are fed from the front. High speed, high accuracy, a long lifetime to make ready electrode without burr, to get a good consistency.

The max die dimension of this pouch cell die cutter is 300*300mm, also we can provide various shapes of knife dies according to customer requirements to realize the forming and die-cutting of battery pole pieces of different sizes.

Features

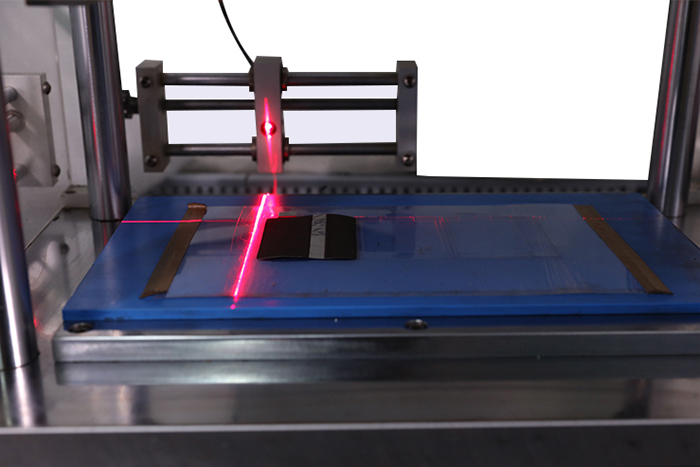

1. Using infrared positioning device, accurate and convenient pole piece positioning die-cutting.

2. Replacement of die cutter is convenient, quick, and consumable (die cutter is life about 30000 times).

3. Long tool life, normal use ≥30,000 times.

4. There are no quality defects such as burrs, powder falling, and indentation.

5. Between manual and fully automatic, high efficiency 800~2000 pieces/hour

(According to the size of the die-cut pole piece, 1-8 pieces can be punched each time, the standard is 2 pieces).

6. Using four guide pillar structure, sliding up and down smoothly and 7. The equipment inlet has a safety. protection light curtain, which makes the operation very safe.

8. Exquisite appearance, the sheet metal adopts a three-dimensional geometric design, which is simple and beautiful.

9. Easy to operate, safe and reliable, small size.

Specification

Model No. | JT-BDC |

| Using an infrared positioning device, accurate and convenient pole piece positioning die cutting | |

| Vertical burr≤15μm, horizontal burr≤20μm | |

| Long tool life, normal use ≥30,000 times | |

| Punching size | 280x180mm (can be customized according to customer requirements) |

| Punching accuracy | ±0.1 mm |

| Booster cylinder | 3T |

| Die cutting stroke | 150mm |

| Pneumatic-liquid pressurized cylinder driven, punching force and punching speed are adjustable | |

| Capacity | 800~2000EA/H (sheet die cutting efficiency is slightly lower) |

With safety protection light curtain | |

| Power supply | 220V/50Hz |

| Power | 100W |

| Compressed air | 0.5Mpa~0.8 Mpa |

| Dimensions | L590xW415xH900mm |

| Equipment weight | 190KG |

Detail

__________________________________

Email: [email protected]

Tel/WhatsApp: +86 18598065580

Skype: [email protected]

Wechat: +86 18598065580

Scan To Wechat