Pouch Cell Assembly Machine Polymer Battery Lab Research Line

Jingtong Battery Equipments offers the most professional pouch cell and supercapacitor assembly line equipment for battery research and manufacturing.

Item No.: JT-WM-P-2

Compliance: CE Certified

Order (MOQ): 1 Set

Payment Terms: T/T, L/C, Western Union

Product Origin: China

Warranty: One Year warranty with lifetime support

Lead Time: 7 Days

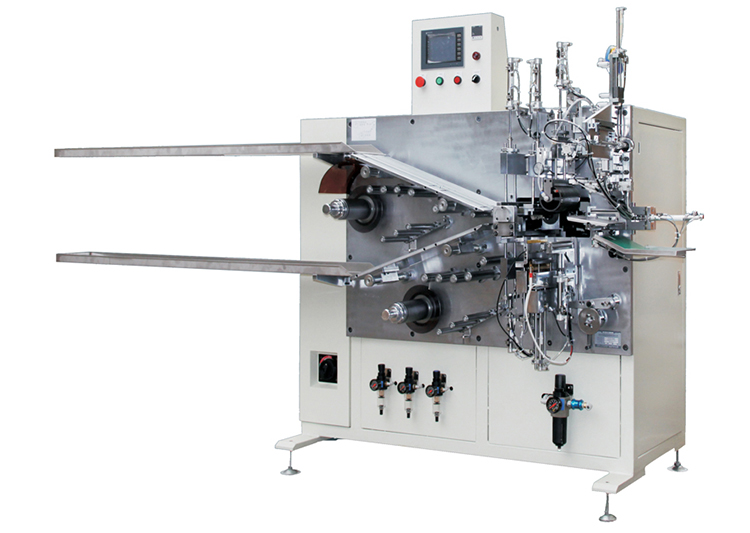

PLC Touch Screen Control Battery Electrode Core Winding Machine For Pouch Cell

The battery winding machine is a semi-automatic electrode winding machine used for lithium Prismatic battery precision winding for the production line. and suitable for the different models of battery by changing the winding blade, The change work is a simple operation.

Feature

1. Adopt a double needle structure, winding needle width can be adjusted continuously.

2. Artificial feeding electrode, automatic winding, automatic needle change, automatic termination of adhesive tape and automatic blanking.

3. Adopt an Embedded controller to realize the battery winding tension control, Using MATLAB to analyze battery separator diameter and roller core change, to generate the best fitting curve control winding process.

4. With functions of electronic CAM, to achieve single circle infinitely variable speed, effectively reduce the angular acceleration

5. Feeding and winding synchronous drive, don't need to follow, real-time transmission

6. The most advanced tension control system Can make batteries without outside tight inside loose phenomenon, effectively reducing the "S" shape problem that occurred.

7. With electrode dust removal system.

8. Electrode tension control as PIC 1.

Specification

Winding size | width 40-100mm, length 30-100mm, thickness 10mm |

Winding accuracy | neatness is better than 0.5mm |

Needle winding form | double-insertion trapezoidal winding needle, standard width 60mm |

Guide length | 1000mm, pole piece can be slightly longer |

Film cutting method | automatic cutting |

Tension control | can be set within 150g |

Width adjustment | Manually adjust the winding needle adjustment within 10mm, the excess part needs to be replaced |

Winding speed | adjustable on the touch screen |

Positive and negative ears | position can be set by motor unwinding |

Adhesive Tape Placement | provide automatic tape dispenser, manual tape |

Air source | 0.5~0.8MPa compressed air |

Power source | voltage single-phase AC220V±10% (110VAC can be customized), frequency 50Hz/60Hz, power 1KW |

Equipment size | L1300mm*W700mm*H920mm |

Weight | About 360KG |

Product Image

__________________________________

Email: [email protected]

Tel/WhatsApp: +86 18598065580

Skype: [email protected]

Wechat: +86 18598065580

Scan To Wechat